Stage 3: Refurbishing the Polo WRC's engine

Two months ago, in this article, we told you about the progress of the Stage 3 project on our customer's Polo WRC. Today, in this article (taken from our video available at the end of the article), we follow the engine rebuild process step by step. From dismantling the engine block and cylinder head to meticulous inspection and component replacement, the experts at Perron & Gay guide us through the intricate details of engine refurbishment.

Visit to Atelier d'Usinage Perron & Gay

Once the engine block and cylinder head have been prepared, it's time to visit the machine shop for the various stages. So off we go to Peron & Gay, a company based in Chambray-lès-Tours that specialises in engine machining. in the workshop, we meet José, a machining expert with over 42 years' experience. He takes us through the various machines and processes he uses to machine and grind engine components. José explains that each workstation is independent and requires specific expertise. The workshop has both traditional and digital machines, depending on the type of work to be carried out.

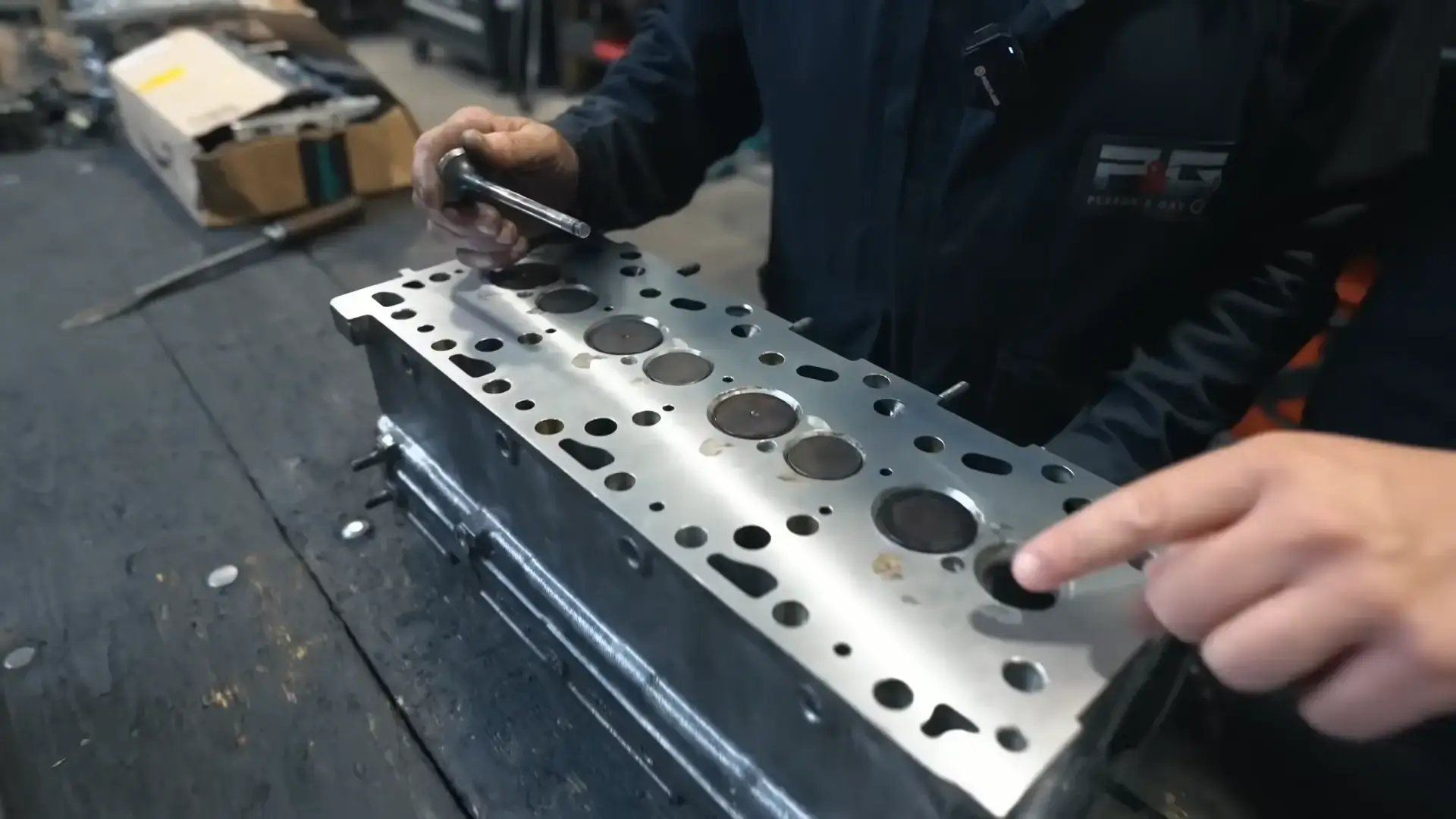

Preparing the engine block and cylinder head

Cleaning and inspection

Before you can assemble the engine, it' s vital to prepare the engine block and cylinder head correctly. These steps ensure that all the parts fit perfectly and function optimally. The first step is to clean and inspect the engine block and cylinder head. All parts must be free of dirt, grease and other contaminants so that any cracks can be seen.

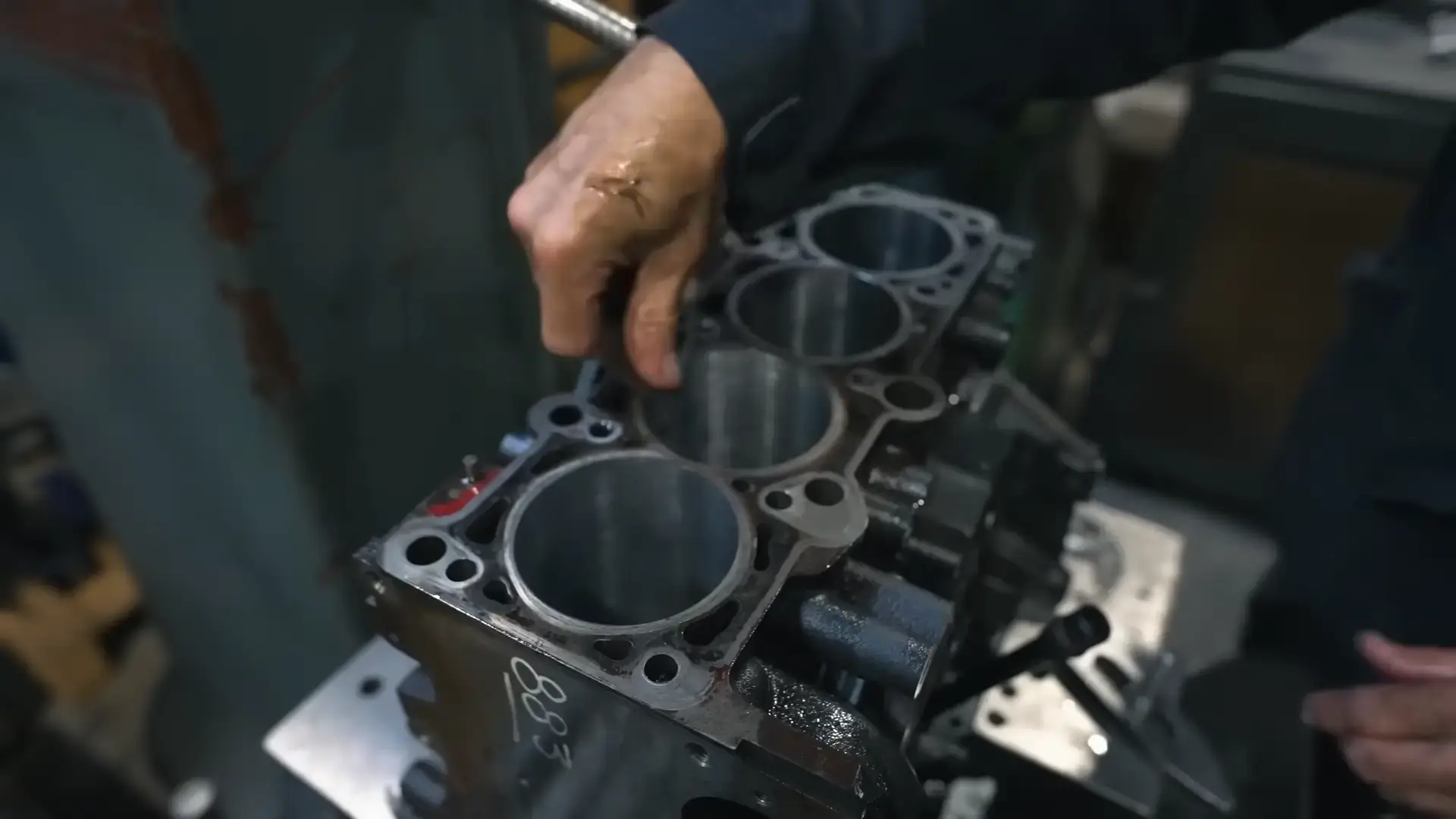

Machining the cylinders

To fit the new forged pistons, the cylinders need to be re-bored to fit the new pistons. The cylinders are measured to determine their ovality. Repair pistons, slightly larger than the original pistons, are used to compensate for this ovality.

Preparing the cylinder head

Cylinder head preparation involves removing the valves, springs and cups. The cylinder head is then sent for a clean gasket and leak test. Once these steps have been completed, the cylinder head is ready for reassembly with new parts, ensuring optimum performance.

cylinder head testing

Cylinderhead testing consists of checking the cylinder head for leaks. The cylinder head is immersed in water and pressurised to detect any leaks. If bubbles appear, the cylinder head is cracked and needs to be repaired or replaced. This step is crucial to ensure that the engine runs smoothly.

Reassembling the cylinder head

After all these steps, the cylinder head is ready to be reassembled. The valves, springs and cups are reinstalled, and the cylinder head is secured to the engine block. Reassembling the cylinder head is a delicate operation that requires a great deal of precision. Once this stage is complete, the engine is almost ready for assembly and testing.

Rectifying the valve seats

Once the cylinder head has been tested, the next step is to analyse and rectify the valve seats. The valve guides are also inspected and replaced if necessary. Rectifying the valve seats ensures optimum sealing and engine performance. It's a delicate stage that also requires attention to ensure great precision.

Machining and reassembly of the engine block

Machining the engine block

Machining the engine block is a critical stage in ensuring that the new pistons fit perfectly. José uses a special machine to bore the cylinders to the correct dimension. Once the cylinders have been bored, they are deglazed to obtain a smooth, uniform surface. This reduces wear and improves engine performance.

Sharpening cylinders and checking crankshaft bearings

Sharpening the cylinders and checking the crankshaft bearings are important steps in ensuring that the engine runs smoothly and lasts a long time. These processes ensure that all parts fit perfectly. The cylinders are measured to determine ovality. They are then honed to the exact dimension required. Thorough cleaning is essential after sharpening to remove chips and other debris.

Checking the crankshaft bearings

Checking the crankshaft bearings is essential to avoid serious mechanical problems. This step ensures that the crankshaft rotates freely and without excessive friction. Crankshaft bearings are inspected for signs of wear or damage. If any anomalies are found, the bearings must be rectified or replaced to ensure optimum reliability.

Engine rebuild costs

Reconditioning costs vary depending on the condition of the engine and the parts required. The following is an estimate of typical costs for different stages of rebuild:

- cylinder head test: €90 excluding VAT

- Cylinder head grinding (4 cylinders): €81 excluding VAT

- Engine block grinding (4 cylinders): €280 excluding VAT

These costs can quickly increase if additional parts need to be replaced or if further repairs are required.

Engine rebuild services

Engine rebuild services include several stages, from initial inspection to final reassembly. Each step is important and critical to ensuring engine performance. Customers can choose to have their entire engine overhauled or just certain stages, depending on their needs and budget.

Working remotely and sending parts

It is possible to work remotely with specialist workshops. Engines can be sent for overhaul and returned after work. This service is particularly popular with customers who can't physically visit the workshop but want the benefit of specialist expertise.

Conclusion

In conclusion, this video offers a complete and detailed insight into the engine rebuild process. Every stage, from cleaning to machining the components, is essential to guarantee the engine's performance and reliability. The expertise of the professionals at Perron & Gay, and in particular José's extensive experience, ensure that the quality of the work is beyond reproach.

Thank you for taking the time to read this article, which we hope you found interesting!

see you soon for the rest of this Stage 3 project!

EVERYTHING YOU NEED TO KNOW!

Watch our video on the Shiftech TV channel!

Learn more

View articles

Similar