PPF protective film: Extreme test on our Lamborghini Huracán Technica

What is body protection film really worth in the face of everyday aggression? At Shiftech, we decided to push PPF to the limit. Spanners, screwdrivers, wire brushes, spray paint and even fire. Our Lamborghini Huracán Technica has been through it all. Here are the results of our uncompromising test.

An essential clarification before getting started

At Shiftech, we test our products in real, extreme conditions to ensure total transparency. If you'd like to know all our prices - whether for a front panel, full protection or a change of appearance - all detailed prices are available directly on our website.

PPF, the invisible protection that changes everything

Paint Protection Film (PPF) has become an essential tool for preserving a vehicle's condition. Made from polyurethane, this transparent or tinted film, 160 to 250 microns thick, is applied directly to the paintwork and absorbs damage instead of the bodywork.

Contrary to popular belief, PPF is not just for supercars: new vehicles, classic cars, commercial vehicles, 4x4s and motorbikes can also benefit.

The practical benefits of PPF film

- Multi-level protection against scratches, stone chips, UV rays, chemical sprays and bird droppings.

- Self-healing: micro-scratches disappear with heat.

- Easy maintenance: water-repellent effect, easy to clean.

- Aesthetic customisation: gloss, satin, matt, carbon.

- Durability: up to 10 years without noticeable deterioration.

On our Huracán Technica, we opted for full satin protection, transforming its original gloss black into a deep, elegant black.

Important addition: precutting, a key stage in professional installation

Why use precut?

PPF is cut to size before installation using a plotter. The film is cut precisely to the shape of the vehicle: bonnet, wings, bumpers, rear-view mirrors, etc.

"There are several types of application. Precut. So basically a precut is... we have a plotter there, which cuts out the perfect film for the bonnet with the right distances and everything. We prefer to do precut. it avoids using a cutter on your car. "

The advantages

- No cutters on the bodywork: no risk of accidental scratches.

- A clean, reliable fit: the film moulds perfectly to the shape of your car.

The natural disadvantage of precut

This application sometimes leaves an unprotected micro-edge (<1 mm).

"Often, we'll have edges... less than a millimetre... that aren't protected. "

But this area is never the most likely to be attacked: we always scratch the middle of an element, never the very bottom edge of a wing.

Why Shiftech favours precutting

The 'full wrap' method (film tucked behind each panel) may seem more aesthetically pleasing, but :

- it creates more tension,

- increases the risk of delamination,

- generates more after-sales service.

Precut, on the other hand, guarantees :

- excellent durability,

- clean, controlled installation,

- perfect edge adhesion.

That's why we use it in the vast majority of cases.

The test protocol: how far can the PPF resist?

To measure the effectiveness of transparent body protection film, we compared :

- The bonnet of a BMW 335i without protection, 150,000 km.

- The bonnet of a Lamborghini covered in PPF.

Each attack was applied simultaneously to both surfaces.

Mechanical damage

Key test: deep scratches on the BMW; superficial marks on the PPF.

Screwdriver: the varnish on the BMW was damaged immediately. The Lamborghini's film absorbs the pressure.

Wire brush: the sound impact is frightening... but the marks on the PPF largely disappear with heat.

Animal scratches: irreparable on bare paintwork; superficial marks on PPF.

abrasive sponges: here again, the paint suffers, not the film.

Chemical and thermal aggression

Spray paint: a nightmare on varnish, but easily removed from PPF.

Ignition: the most extreme test. On the BMW bonnet, discolouration and deep marks. On the protected Lamborghini: no visible damage after cleaning.

Self-healing: myth or reality?

After exposure to the sun, the micro-scratches left by the keys and wire brush have faded. Polyurethane has a shape memory: when heated, it shrinks and corrects slight deformations.

Deeper damage alters the surface of the film, but not the bodywork, which is precisely the role of PPF.

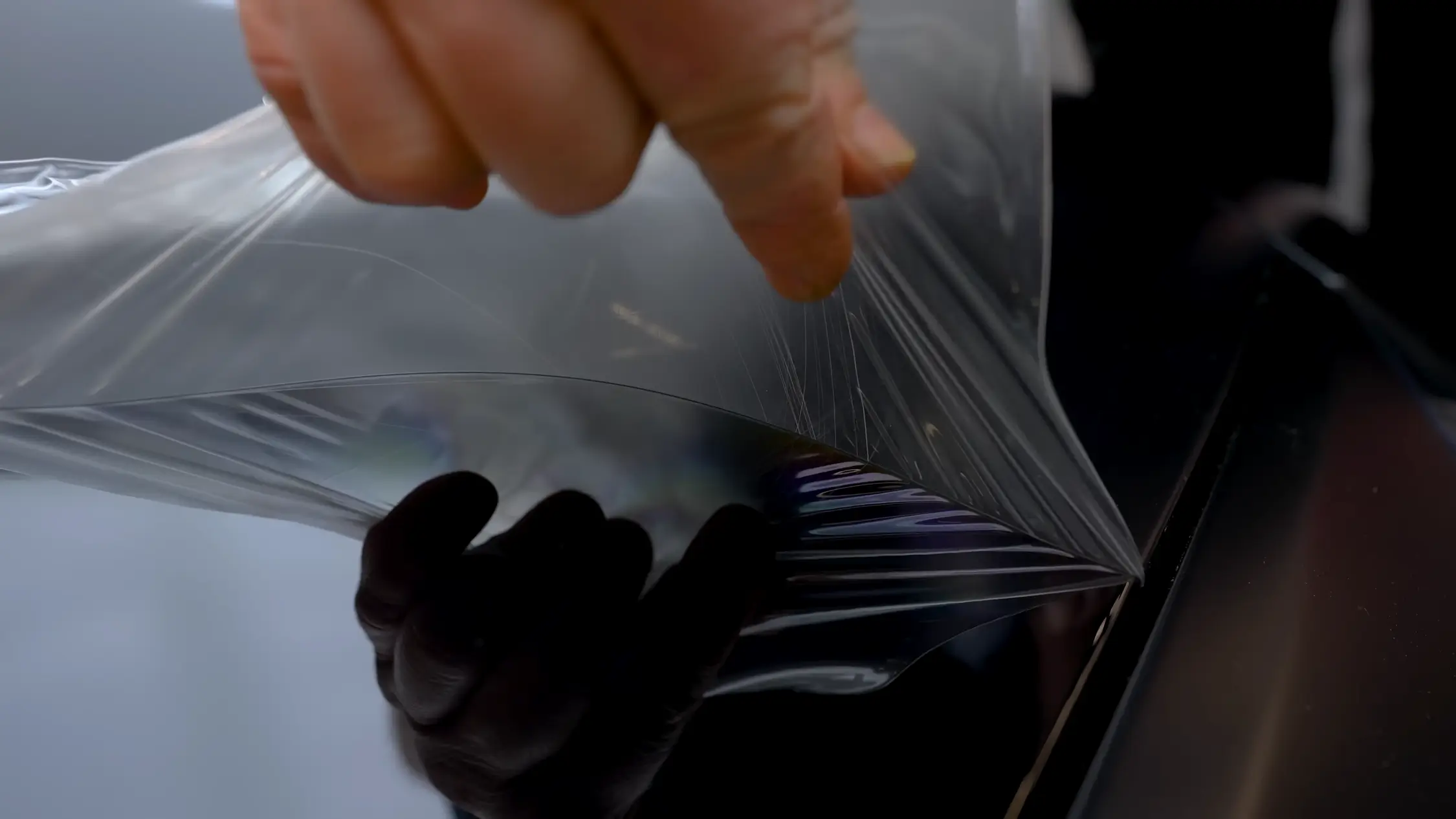

The moment of truth: withdrawal from the film

After subjecting the film to extreme aggression, its removal reveals a simple truth: the bodywork is intact.

No scratches. No burns. No discolouration. Only a few glue residues need cleaning. The difference with the BMW bonnet, covered in deep scratches, is spectacular.

Verdict: PPF works - and is the absolute benchmark in body protection

Having withstood the mechanical, chemical and thermal stresses of a disaster scenario without flinching, it's clear: PPF is not only effective, it pushes back the limits of what you can expect from modern bodywork protection.

This film absorbs what no paintwork could tolerate, absorbs the impossible, preserves the visual integrity of the vehicle and keeps its value intact. Where a bare body becomes a battlefield, PPF emerges victorious, ready to fight again.

- it stands up where all other treatments fail,

- it protects the bodywork like invisible armour,

- it maintains the original appearance despite the worst of the aggression,

- it prolongs a vehicle's value like no other solution on the market.

at this level of resilience, we're no longer talking about simple protection: we're talking about the best bodywork defence available today.

The truth on video!

PPF protective film: We're testing the Lamborghini's resistance ( I'm setting it on fire )

Learn more

View articles

Similar